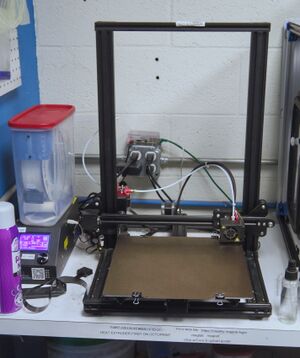

Creality CR10S

History

The Creality-CR10S was donated by Kyle. Thanks.

The glass build bed was donated by Michael.

Hotend

The hotend was previously clogged with a giant blob of PLA. Please watch your prints through the first layer at least. Not all prints will succeed, but you are more likely to succeed after the first layer is printed.

The thermistor on the hotend was replaced on 2022-07-20. Problems were noted in June.

Bed

The build surface was blue tape when the printer was first donated. The build surface was the Creality "Carborundum" tempered glass bed. As of 2022-08-22, the bed is binder-clipped, PEI coated steel.

Operator's Log

2022-08-26 Yangbot

Bed adhesion issues noted when printing bike handlebar spacers.

2022-08-28 Brandon

Bed adhesion issues confirmed.

Bed leveling was completed successfully, but there is a significant dip in the center and center, right side of the 3d printer bed. Bed leveling shows concerning data:

| 0.2mm leveling data | ||

|---|---|---|

| 0.225 | 0.225 | 0.275 |

| 0.225 | -0.050 | 0.000 |

| 0.275 | 0.250 | 0.300 |

2022-09-02 Brandon

Nozzle was severely clogged with burnt plastic. Nozzle replaced.

The clogged nozzle could have caused the issues on 2022-08-26, but a bed leveling was also performed. Additionally, extrusion on the first layer is increased to 120%.

2022-09-03 Brandon

Bed leveling completed and bike handlebar adapter from Thingiverse successfully printed.

The bed is still severely unlevel in the middle and center-right corner.

In order to adhere to the rough PEI surface, the printer was leveled 0.1mm lower than the measured height. This is done so that the first layer of extruded plastic will flow around the rough PEI coated texture on the bed and create a stable mechanical bond.