PCB notes: Difference between revisions

Jump to navigation

Jump to search

mNo edit summary |

m (→Router milling: Added linuxcnc notes.) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

=PCB making notes= | =PCB making notes= | ||

| Line 37: | Line 35: | ||

Using a CNC router to perform isolation milling | Using a CNC router to perform isolation milling | ||

LinuxCNC mill notes can be found [[CNC_Mill#FlatCAM Parameters|here]]. | |||

---- | ---- | ||

==Etching== | ==Etching== | ||

[[Category:Notes]][[Category:Projects]] | |||

Latest revision as of 08:37, 19 May 2025

PCB making notes

Various notes about PCB making using MAGLabs equipment.

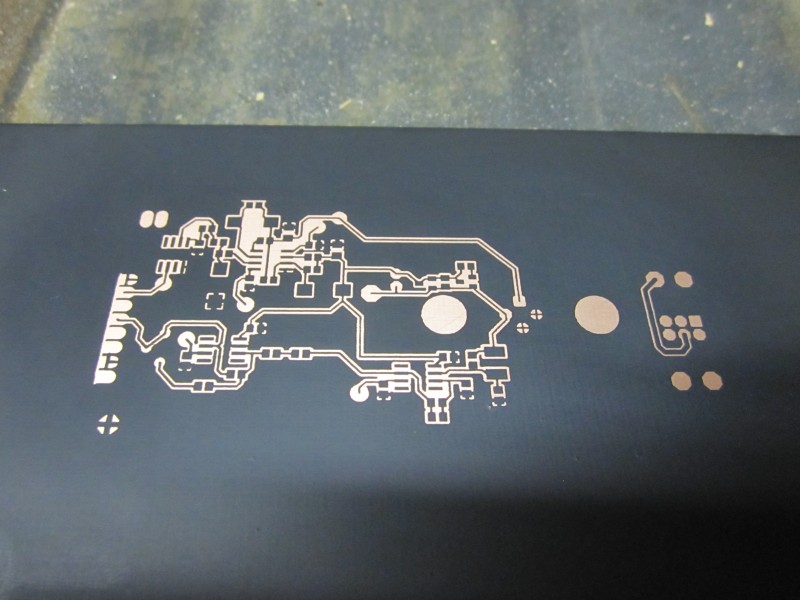

Laser Etching

Using the laser cutter to remove mask before etching. Minimum feature size of 12 mil can work. Be sure to use ground fill planes in order to minimize amount of material to be removed by laser and etching.

- Prepare the board by coating with flat black spray paint

- Export layout as a 600 DPI black and white bitmap. Invert the image as the black portions will be cut away by the laser.

- Load bitmap into Corel Draw.

- Configure laser to use 19% power and 50% speed with 500 PPI and raster scan.

- Laser cut away paint.

- Scrub away burnt region using toothbrush and toothpaste

- Success

Router milling

Using a CNC router to perform isolation milling

LinuxCNC mill notes can be found here.