Epoxy Granite CNC Tabletop Mill: Difference between revisions

Jump to navigation

Jump to search

Semeiotike (talk | contribs) No edit summary |

Semeiotike (talk | contribs) No edit summary |

||

| Line 5: | Line 5: | ||

29 July 2013 | 29 July 2013 | ||

A couple of months have elapsed since we finished the EG base and I feel comfortable saying that designing and casting a composite base | A couple of months have elapsed since we finished the EG base and I feel comfortable saying that designing and casting a composite base may be a good idea for some applications, depending on your machine requirements and with only a few reservations that I will go into later. | ||

Below, I will go over the basic process that we used to make our base. | Below, I will go over the basic process that we used to make our base. | ||

Revision as of 21:33, 29 July 2013

Return to Projects Projects

Post Project Report "ALL OUR CNC BASE"

29 July 2013

A couple of months have elapsed since we finished the EG base and I feel comfortable saying that designing and casting a composite base may be a good idea for some applications, depending on your machine requirements and with only a few reservations that I will go into later.

Below, I will go over the basic process that we used to make our base.

Update History

30 May 2013

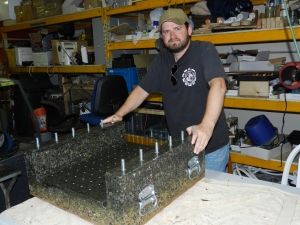

The base has been molded YES!! (fist pumping).

20 Apr 2013

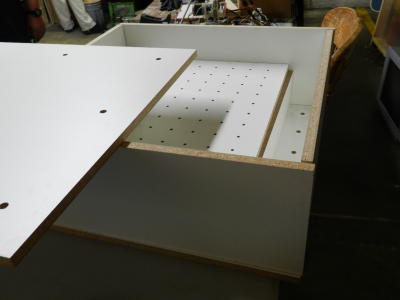

Parts (on order) have been rolling in, mold assembly has started.

Status 4 Feb 13

Mold has been made, waiting for planning of plumbing (cutting fluids) and parts (fastener and epoxy)